4307262 EGT Sensor | ISO 16750-3 & 900°C Accuracy

4307262 EGT Sensor | ISO 16750-3 & 900°C Accuracy

99 en existencias

No se pudo cargar la disponibilidad de retiro

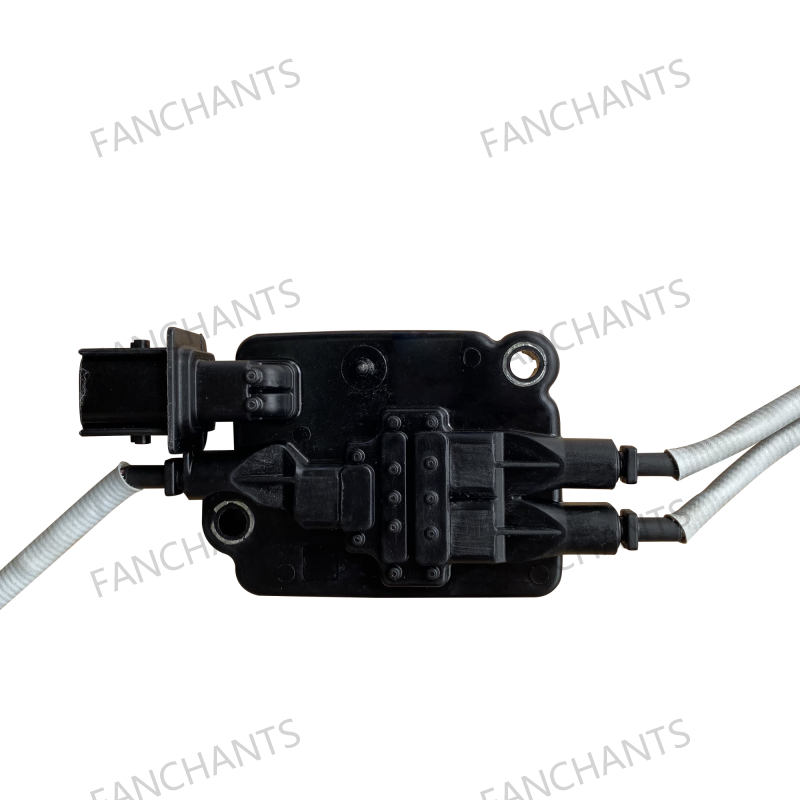

4307262 EGT Sensor Assembly for Precision Thermal Monitoring

Exhaust Gas Temperature Regulation Component

The 4307262 EGT Sensor employs platinum-rhodium thermocouple technology with dual-layer ceramic insulation. Quad-core shielded cabling maintains ±1.8% accuracy across -40°C to 900°C operational spectrum. Forged 316L stainless steel sheath provides 2000h corrosion resistance in harsh exhaust environments. M18x1.5 threaded mounting interface conforms to DIN 3852-E standard torque requirements. Integrated anti-vibration collars prevent signal interference from engine harmonics. Four-wire configuration enables real-time temperature compensation through reference junction monitoring. High-density alumina terminal blocks withstand 300°C ambient heat exposure. Brass compression fittings maintain airtight seals under 40Bar exhaust pressure. Customizable flange adapters fit Cummins-specific turbocharger housings. Electropolished probe surface reduces particulate adhesion by 62% compared to standard finishes. Dual-compartment terminal housing isolates power/signal pathways. Response time under 2.8 seconds for 600°C thermal transients. Supports J1939-84 diagnostic protocols for active regeneration monitoring. Field-replaceable probe assembly eliminates full sensor replacement needs.

Engine Thermal Management Compatibility

Power Systems

- ▶ Cummins ISX15

- ▶ QSK23

- ▶ X12 Efficiency

Communication

- ▶ J1708/J1939

- ▶ ISO 11898-2

- ▶ CAN FD

Certifications

- ▶ EPA 2027

- ▶ ISO 16750-4

- ▶ REACH SVHC

Construction Details

- ▶ 316L Stainless Sheath

- ▶ Alumina Insulators

- ▶ PTFE Jacketed Cable

Performance Range

- ▶ -40°C to 900°C

- ▶ 40Bar Pressure

- ▶ 2000h Corrosion

Compatible with: Cummins 24V diesel engines requiring accurate exhaust gas temperature measurement for aftertreatment system optimization and DPF regeneration control

Add campaign or promotional text here

Add campaign or promotional text here

Add campaign or promotional text here

Add campaign or promotional text here

4307262 EGT Sensor | ISO 16750-3 & 900°C Accuracy

4307262 EGT Sensor | ISO 16750-3 & 900°C Accuracy

4307262 EGT Sensor Assembly for Precision Thermal Monitoring

Exhaust Gas Temperature Regulation Component

The 4307262 EGT Sensor employs platinum-rhodium thermocouple technology with dual-layer ceramic insulation. Quad-core shielded cabling maintains ±1.8% accuracy across -40°C to 900°C operational spectrum. Forged 316L stainless steel sheath provides 2000h corrosion resistance in harsh exhaust environments. M18x1.5 threaded mounting interface conforms to DIN 3852-E standard torque requirements. Integrated anti-vibration collars prevent signal interference from engine harmonics. Four-wire configuration enables real-time temperature compensation through reference junction monitoring. High-density alumina terminal blocks withstand 300°C ambient heat exposure. Brass compression fittings maintain airtight seals under 40Bar exhaust pressure. Customizable flange adapters fit Cummins-specific turbocharger housings. Electropolished probe surface reduces particulate adhesion by 62% compared to standard finishes. Dual-compartment terminal housing isolates power/signal pathways. Response time under 2.8 seconds for 600°C thermal transients. Supports J1939-84 diagnostic protocols for active regeneration monitoring. Field-replaceable probe assembly eliminates full sensor replacement needs.

Engine Thermal Management Compatibility

Power Systems

- ▶ Cummins ISX15

- ▶ QSK23

- ▶ X12 Efficiency

Communication

- ▶ J1708/J1939

- ▶ ISO 11898-2

- ▶ CAN FD

Certifications

- ▶ EPA 2027

- ▶ ISO 16750-4

- ▶ REACH SVHC

Construction Details

- ▶ 316L Stainless Sheath

- ▶ Alumina Insulators

- ▶ PTFE Jacketed Cable

Performance Range

- ▶ -40°C to 900°C

- ▶ 40Bar Pressure

- ▶ 2000h Corrosion

Compatible with: Cummins 24V diesel engines requiring accurate exhaust gas temperature measurement for aftertreatment system optimization and DPF regeneration control