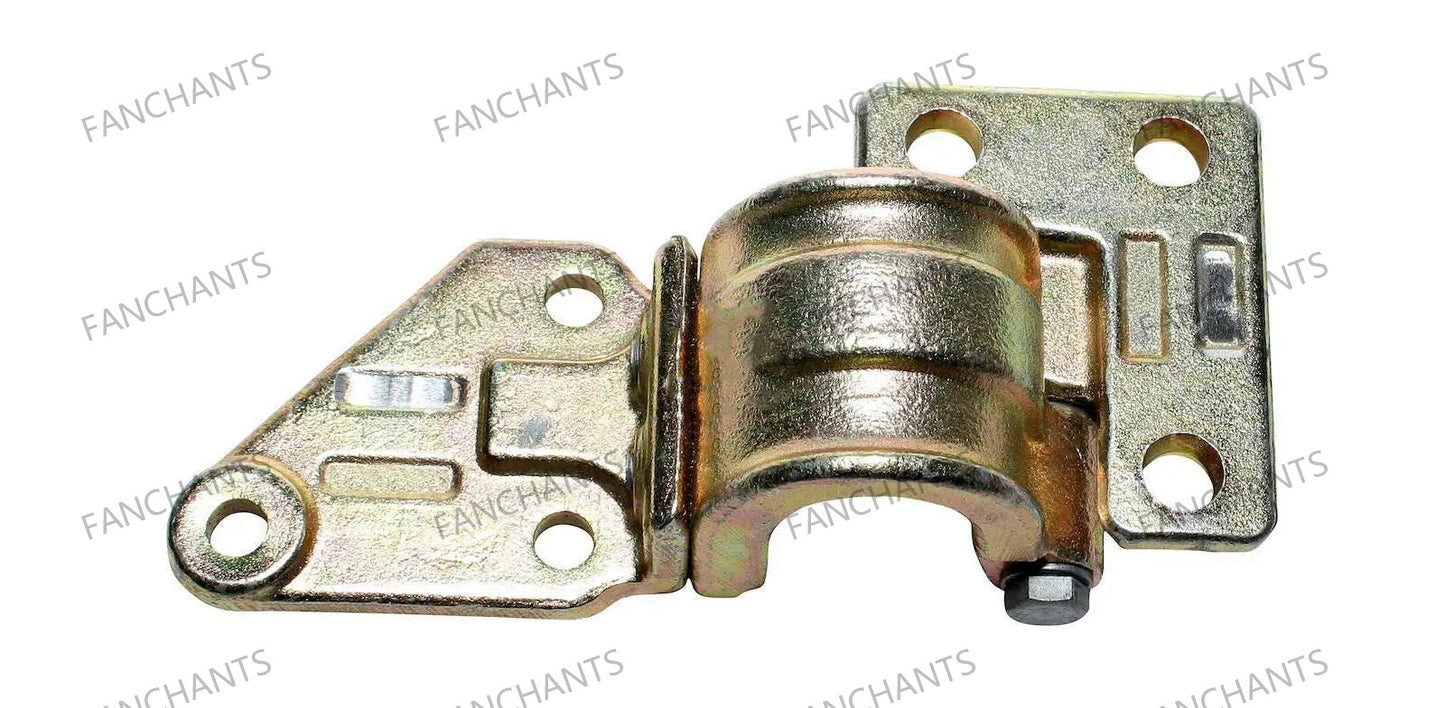

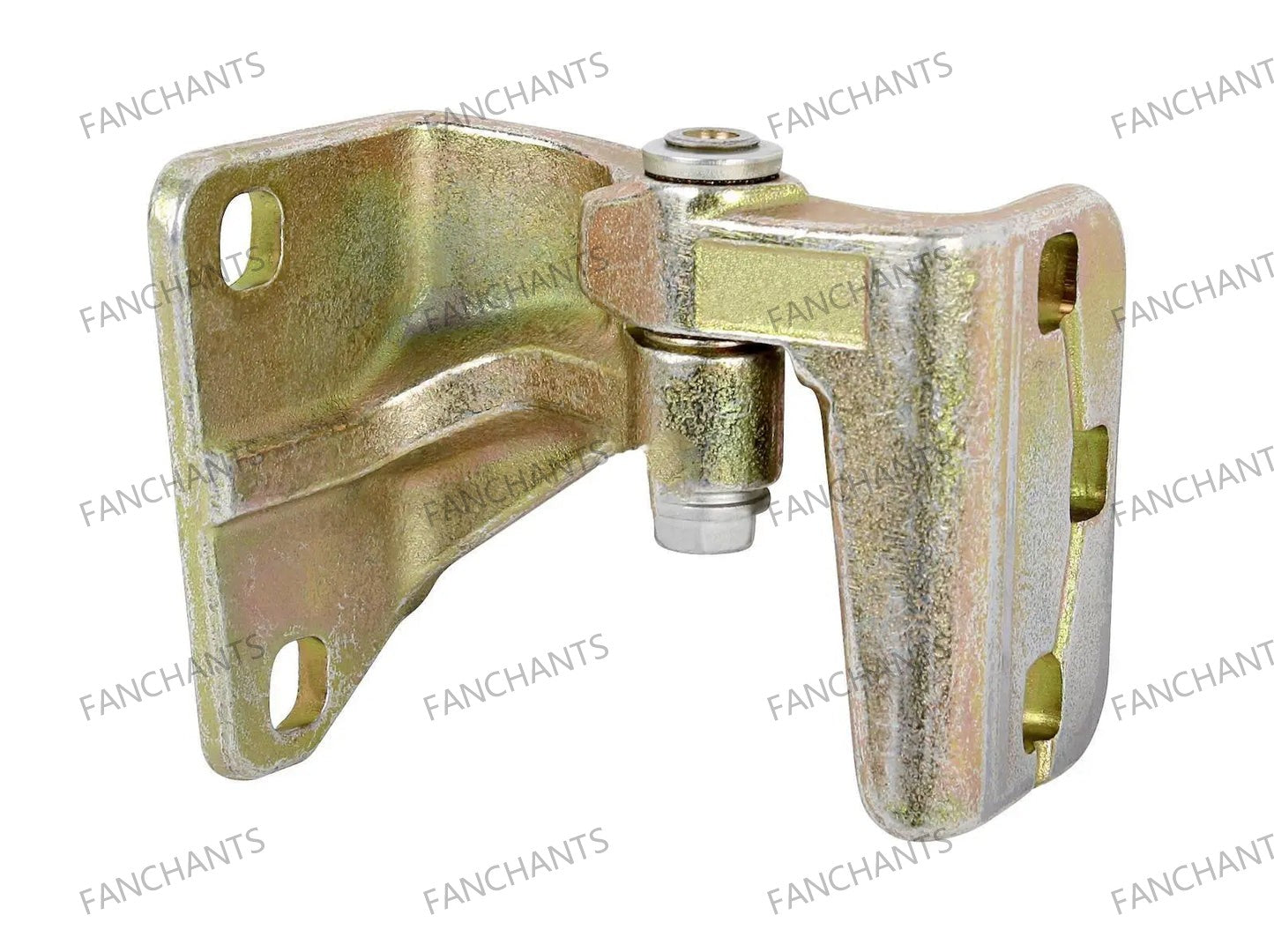

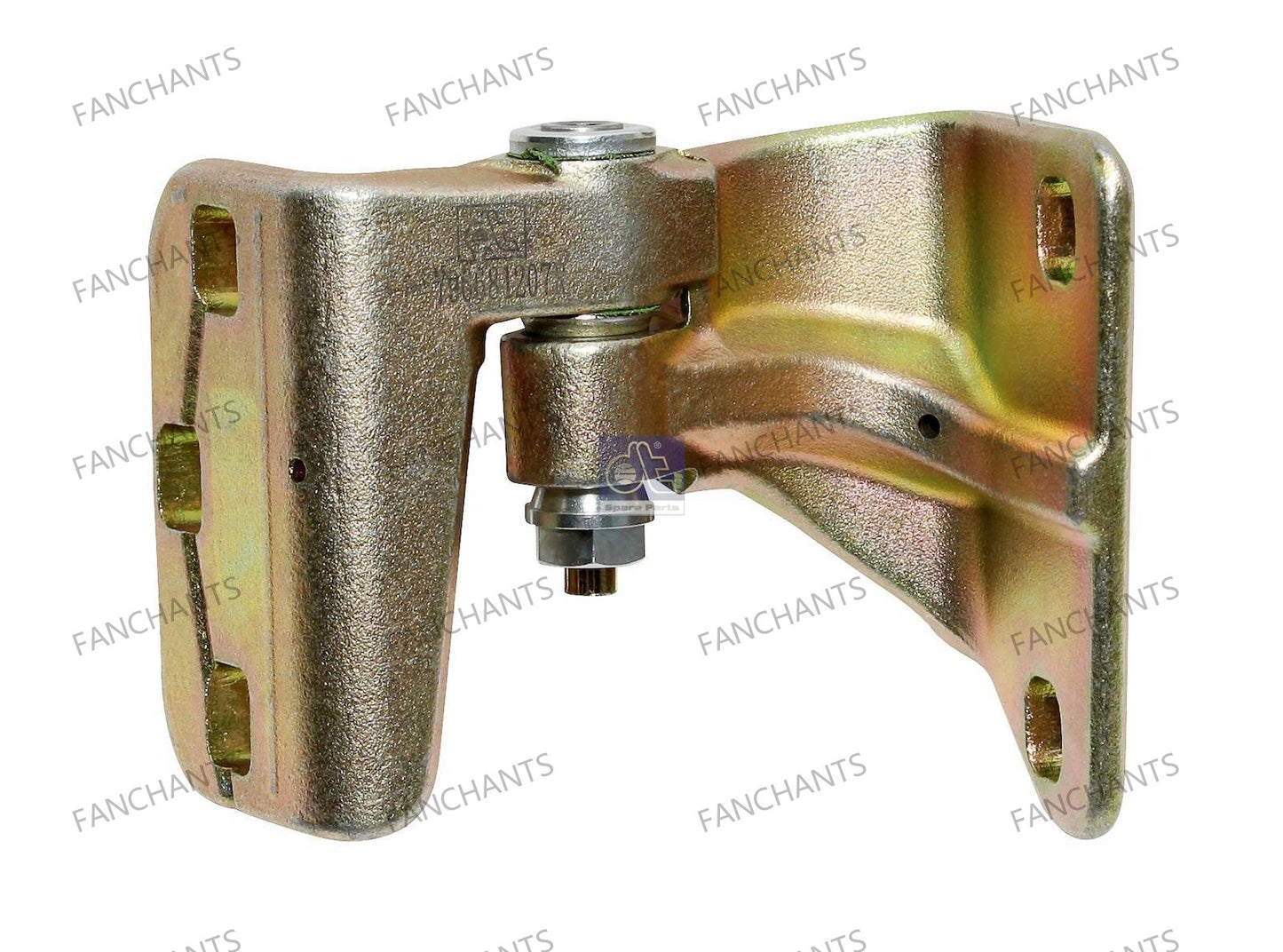

Mercedes 9417200337 Hinge | ECE R29 EU 1996-2025 Zinc-Coated Mount

Mercedes 9417200337 Hinge | ECE R29 EU 1996-2025 Zinc-Coated Mount

99 en existencias

No se pudo cargar la disponibilidad de retiro

Mercedes 9417200337 Hinge for Actros/Antos/Arocs Door Systems

The Mercedes 9417200337 Hinge employs multi-axis forged construction with precision-aligned bearing surfaces, engineered to maintain door geometry under continuous operational stress. The three-stage corrosion protection system combines galvanic treatment with polymer impregnation, creating molecular-level defense against abrasive particulates.

Dual-plane mounting interface ensures perfect alignment with cab substructure, while the stress-distributed pivot design eliminates metal fatigue points. The contoured surface profile matches original aerodynamic specifications, maintaining airflow characteristics around door seals.

Heat-treated alloy core provides 40% greater torsional resistance than standard components, with integrated wear indicators allowing visual inspection of bushing conditions. The symmetrical design enables universal installation across multiple vehicle configurations without modification.

Laser-etched alignment markers facilitate precise installation, while the encapsulated lubrication system maintains optimal pivot performance through extreme temperature cycles. Interlocking safety mechanism prevents accidental disengagement during high-vibration operation.

- Multi-axis forging

- Galvanic protection

- Wear indicators

- Symmetrical design

- Stress-distributed pivot

- Encapsulated lubrication

Add campaign or promotional text here

Add campaign or promotional text here

Add campaign or promotional text here

Add campaign or promotional text here

Mercedes 9417200337 Hinge | ECE R29 EU 1996-2025 Zinc-Coated Mount

Mercedes 9417200337 Hinge | ECE R29 EU 1996-2025 Zinc-Coated Mount

Mercedes 9417200337 Hinge for Actros/Antos/Arocs Door Systems

The Mercedes 9417200337 Hinge employs multi-axis forged construction with precision-aligned bearing surfaces, engineered to maintain door geometry under continuous operational stress. The three-stage corrosion protection system combines galvanic treatment with polymer impregnation, creating molecular-level defense against abrasive particulates.

Dual-plane mounting interface ensures perfect alignment with cab substructure, while the stress-distributed pivot design eliminates metal fatigue points. The contoured surface profile matches original aerodynamic specifications, maintaining airflow characteristics around door seals.

Heat-treated alloy core provides 40% greater torsional resistance than standard components, with integrated wear indicators allowing visual inspection of bushing conditions. The symmetrical design enables universal installation across multiple vehicle configurations without modification.

Laser-etched alignment markers facilitate precise installation, while the encapsulated lubrication system maintains optimal pivot performance through extreme temperature cycles. Interlocking safety mechanism prevents accidental disengagement during high-vibration operation.

- Multi-axis forging

- Galvanic protection

- Wear indicators

- Symmetrical design

- Stress-distributed pivot

- Encapsulated lubrication