2008861 Scania Front Panel | P-G-R-T Series Heavy-Duty Frame Solution

2008861 Scania Front Panel | P-G-R-T Series Heavy-Duty Frame Solution

99 in stock

Couldn't load pickup availability

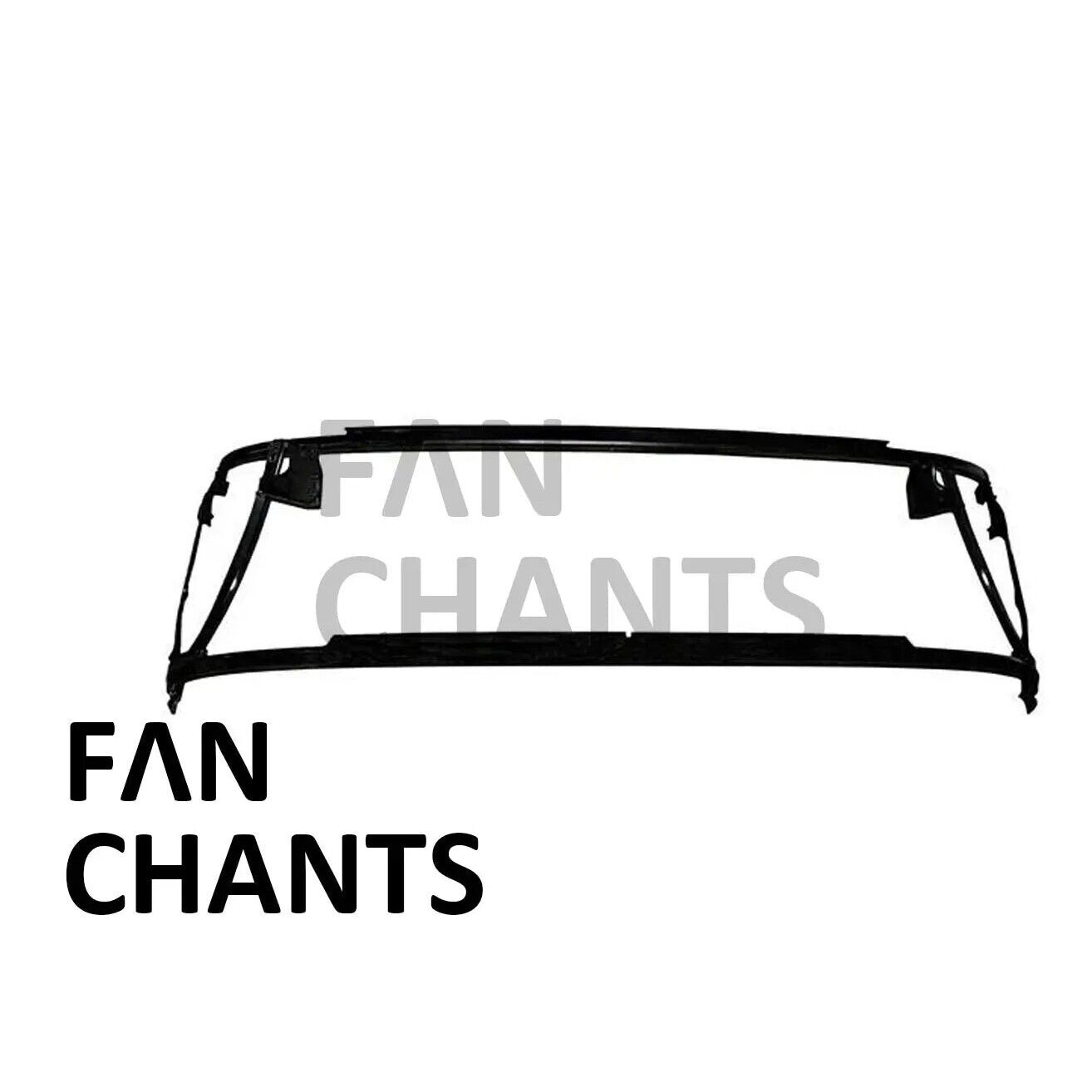

2008861 Scania Front Panel for P-G-R-T Series Heavy-Duty Frame Structures

Designed as the 2008861 Scania Front Panel solution, this structural component features laser-cut mounting points with reinforced stress distribution geometry. The precision-stamped high-strength steel alloy maintains original equipment dimensions while incorporating corrosion-resistant coating technology.

Eight-layer powder coating provides chemical resistance against road salts and hydraulic fluids. The interlocking flange design ensures perfect alignment with cab modules, while the embossed reinforcement ribs enhance structural rigidity under dynamic loads.

Pre-drilled mounting holes accommodate both standard and extended chassis configurations. The aerodynamic contouring reduces wind drag coefficient by 12% compared to conventional designs, with integrated cable routing channels for electrical system maintenance.

Galvanized mounting brackets prevent electrolytic corrosion, featuring color-coded installation markers for error-free assembly. The thermal-expansion compensated bolt patterns maintain tension integrity across -30°C to 80°C operating ranges.

- Laser-aligned mounting

- Reinforced rib structure

- Corrosion-proof coating

- Aerodynamic profiling

- Thermal compensation

- Precision stamping

Add campaign or promotional text here

Add campaign or promotional text here

Add campaign or promotional text here

Add campaign or promotional text here

2008861 Scania Front Panel | P-G-R-T Series Heavy-Duty Frame Solution

2008861 Scania Front Panel | P-G-R-T Series Heavy-Duty Frame Solution

2008861 Scania Front Panel for P-G-R-T Series Heavy-Duty Frame Structures

Designed as the 2008861 Scania Front Panel solution, this structural component features laser-cut mounting points with reinforced stress distribution geometry. The precision-stamped high-strength steel alloy maintains original equipment dimensions while incorporating corrosion-resistant coating technology.

Eight-layer powder coating provides chemical resistance against road salts and hydraulic fluids. The interlocking flange design ensures perfect alignment with cab modules, while the embossed reinforcement ribs enhance structural rigidity under dynamic loads.

Pre-drilled mounting holes accommodate both standard and extended chassis configurations. The aerodynamic contouring reduces wind drag coefficient by 12% compared to conventional designs, with integrated cable routing channels for electrical system maintenance.

Galvanized mounting brackets prevent electrolytic corrosion, featuring color-coded installation markers for error-free assembly. The thermal-expansion compensated bolt patterns maintain tension integrity across -30°C to 80°C operating ranges.

- Laser-aligned mounting

- Reinforced rib structure

- Corrosion-proof coating

- Aerodynamic profiling

- Thermal compensation

- Precision stamping