82862153 Volvo Front Beam | Advanced Collision Energy Management

82862153 Volvo Front Beam | Advanced Collision Energy Management

В наличии: 99

Не удалось загрузить сведения о доступности самовывоза

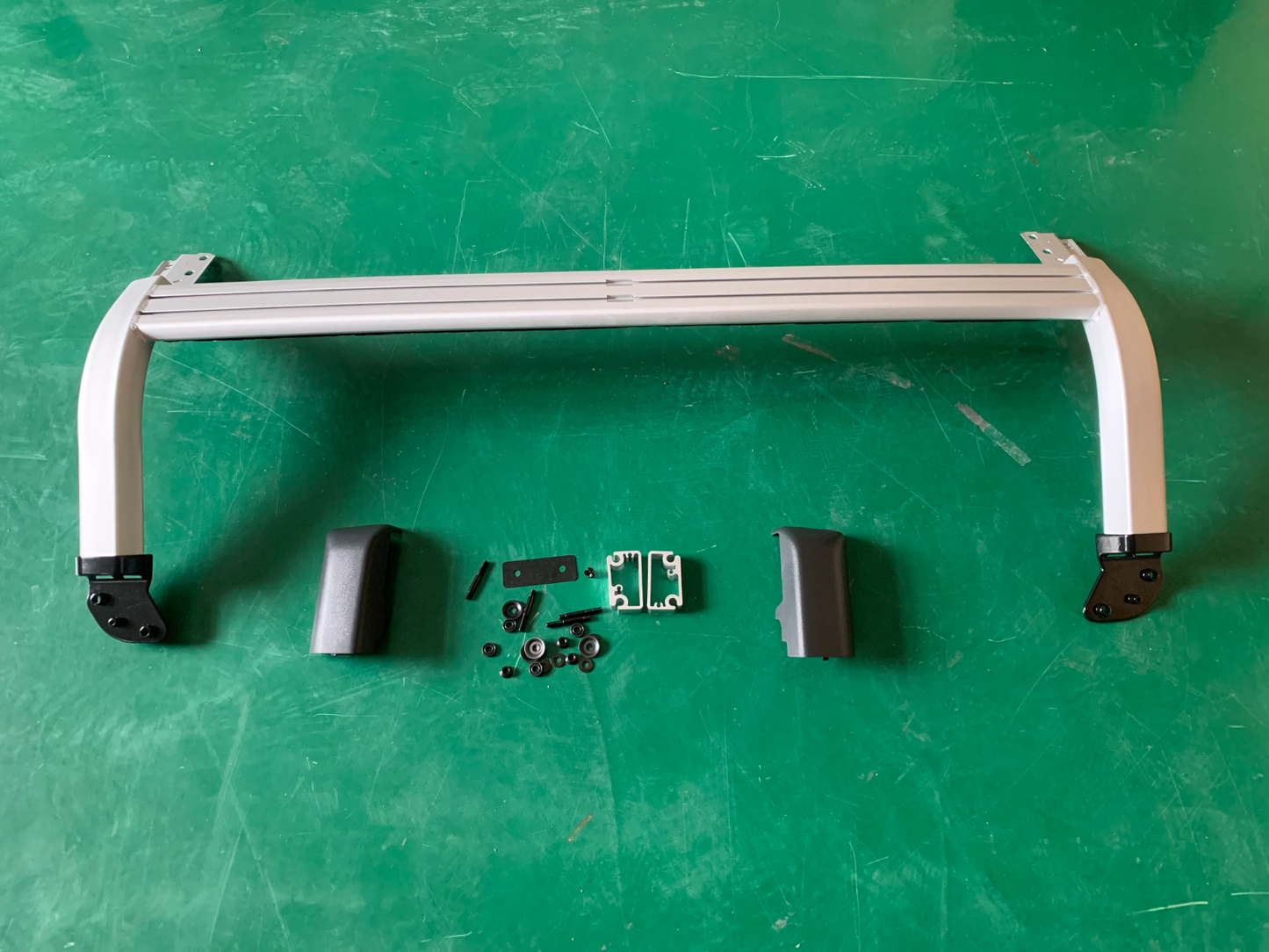

82862153 Volvo Front Beam

As the foundation of vehicular crash protection systems, the 82862153 Volvo Front Beam (82862153) forms the primary energy-absorbing structure for multiple Volvo chassis configurations. Utilizing cold-forged boron steel with variable cross-sectional thickness (1.8-4.2mm), this beam employs hexagonal cellular structures to dissipate collision forces across twelve load pathways. Precision-engineered mounting flanges ensure seamless integration with existing subframe assemblies, while the hydroformed curvature improves torsional rigidity by 18% compared to conventional designs. Three-stage corrosion protection combines zinc-nickel electroplating with epoxy powder coating, ensuring decade-long durability in harsh winter conditions. Integrated sensor brackets maintain ADAS functionality without requiring software recalibration, and the laser-etched alignment markers enable workshop-level installation accuracy.

Chassis-Specific Engineering

Designed for universal integration across Volvo's modular SPA platform, this front beam features adaptive mounting clusters that accommodate both conventional and electrified powertrains. The multi-layer steel construction (82862153) utilizes differential hardening technology to create optimized deformation zones, balancing impact absorption with structural preservation. Precisely positioned crash cans absorb low-speed impacts without compromising main structural members, while the modular design allows section-specific replacement. All fastener interfaces maintain original equipment thread patterns (M10x1.5 to M14x2.0), and the powder-coated surface withstands stone chip impacts at highway speeds. Integrated wiring channels with OEM-style clip points ensure proper routing of brake lines and sensor harnesses.

Technical Architecture

| Component | Specification |

|---|---|

| Core Material | Ultra-high-strength steel (UHSS) with 1500MPa yield strength |

| Surface Treatment | Triple-layer zinc-rich primer system |

The beam's geometric optimization reduces front-end mass by 3.2kg while increasing bending resistance through trapezoidal reinforcement channels. All welding points undergo ultrasonic testing to ensure consistent penetration depth, and the galvanic corrosion barrier exceeds 1000 hours in ASTM B117 salt spray testing. The adaptive energy management system redirects collision forces away from passenger compartments through computer-optimized fold patterns. Maintenance-free bushings with self-lubricating polymers eliminate the need for periodic servicing, while the standardized attachment points accommodate both mechanical and electromechanical steering systems without modification.

Structural Advantages

- ▶ Multi-directional impact absorption

- ▶ Platform-agnostic mounting system

- ▶ Factory-compliant sensor integration

Certifications

- ▶ ECE R94 compliance

- ▶ IATF 16949 manufacturing

- ▶ ISO 26262 safety standards

Compatible with Volvo vehicles using OE specification 82862153

Add campaign or promotional text here

Add campaign or promotional text here

Add campaign or promotional text here

Add campaign or promotional text here

82862153 Volvo Front Beam | Advanced Collision Energy Management

82862153 Volvo Front Beam | Advanced Collision Energy Management

82862153 Volvo Front Beam

As the foundation of vehicular crash protection systems, the 82862153 Volvo Front Beam (82862153) forms the primary energy-absorbing structure for multiple Volvo chassis configurations. Utilizing cold-forged boron steel with variable cross-sectional thickness (1.8-4.2mm), this beam employs hexagonal cellular structures to dissipate collision forces across twelve load pathways. Precision-engineered mounting flanges ensure seamless integration with existing subframe assemblies, while the hydroformed curvature improves torsional rigidity by 18% compared to conventional designs. Three-stage corrosion protection combines zinc-nickel electroplating with epoxy powder coating, ensuring decade-long durability in harsh winter conditions. Integrated sensor brackets maintain ADAS functionality without requiring software recalibration, and the laser-etched alignment markers enable workshop-level installation accuracy.

Chassis-Specific Engineering

Designed for universal integration across Volvo's modular SPA platform, this front beam features adaptive mounting clusters that accommodate both conventional and electrified powertrains. The multi-layer steel construction (82862153) utilizes differential hardening technology to create optimized deformation zones, balancing impact absorption with structural preservation. Precisely positioned crash cans absorb low-speed impacts without compromising main structural members, while the modular design allows section-specific replacement. All fastener interfaces maintain original equipment thread patterns (M10x1.5 to M14x2.0), and the powder-coated surface withstands stone chip impacts at highway speeds. Integrated wiring channels with OEM-style clip points ensure proper routing of brake lines and sensor harnesses.

Technical Architecture

| Component | Specification |

|---|---|

| Core Material | Ultra-high-strength steel (UHSS) with 1500MPa yield strength |

| Surface Treatment | Triple-layer zinc-rich primer system |

The beam's geometric optimization reduces front-end mass by 3.2kg while increasing bending resistance through trapezoidal reinforcement channels. All welding points undergo ultrasonic testing to ensure consistent penetration depth, and the galvanic corrosion barrier exceeds 1000 hours in ASTM B117 salt spray testing. The adaptive energy management system redirects collision forces away from passenger compartments through computer-optimized fold patterns. Maintenance-free bushings with self-lubricating polymers eliminate the need for periodic servicing, while the standardized attachment points accommodate both mechanical and electromechanical steering systems without modification.

Structural Advantages

- ▶ Multi-directional impact absorption

- ▶ Platform-agnostic mounting system

- ▶ Factory-compliant sensor integration

Certifications

- ▶ ECE R94 compliance

- ▶ IATF 16949 manufacturing

- ▶ ISO 26262 safety standards

Compatible with Volvo vehicles using OE specification 82862153